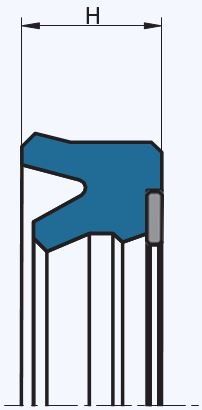

RS117R

Asymmetrical Rod Seal with backup ring.

Suitable for large extrusion gaps and for higher pressure ranges.

With additional sealing or stabilising lip.

Use in telescopic cylinders and special installation spaces.

Material and Application Parameters

| Sealing Element | Support Ring | Temperature (°C) | Max. Sliding Speed (m/s) | Maximum Pressure² | ||

|---|---|---|---|---|---|---|

| HPU Premium | POM / PA6³ | -30 | - | +100 | 0.5 | 400 bar (5800psi) |

| HPU Diet | POM / PA6³ | -20 | - | +100 | 0.5 | 400 bar (5800psi) |

| SLPU | POM / PA6³ | -20 | - | +100 | 0.7 | 400 bar (5800psi) |

| HPU Low Temperature | POM / PA6³ | -40 | - | +100 | 0.5 | 400 bar (5800psi) |

| NBR Standard | POM / PA6³ | -30 | - | +100 | 0.5 | 250 bar (3600psi) |

| FPM Diet | PTFE Glass | -20 | - | +200 | 0.5 | 250 bar (36000psi) |

| EPDM Spring | POM | -50 | - | +100 | 0.5 | 250 bar (36000psi) |

| EPDM Spring | PA6³ | -40 | - | +100 | 0.5 | 250 bar (36000psi) |

| EPDM Spring | PTFE Glass | -50 | - | +150 | 0.5 | 250 bar (36000psi) |

| HNBR Diet | PA6³ | -25 | - | +100 | 0.5 | 250 bar (36000psi) |

| HNBR Diet | PTFE Glass | -25 | - | +150 | 0.5 | 250 bar (36000psi) |

| Aflas Standard | PTFE Glass | -10 | - | +200 | 0.5 | 250 bar (36000psi) |

Standard Dimensions

| Maximum radial extrusion gap s¹ (mm) | |||||||||||

| P² | R² | P² | R² | ||||||||

| Ød f8 (mm) | ØD H10 (mm) | L +0.2mm | H (mm) | C (mm) | 20 bar | 100 bar | 250³ bar | 400 bar | 600 bar | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| ≥23 - ≤25 | d + 8 | 8.00 | 7.80 | 3.50 | 0.80 | 0.60 | 0.80 | 0.80 | 0.52 | 0.30 | 0.11 |

| >25 - ≤50 | d + 10 | 9.00 | 8.70 | 4.00 | 1.00 | 1.00 | 1.00 | 1.00 | 0.66 | 0.37 | 0.14 |

| >50 - ≤150 | d + 15 | 14.00 | 13.60 | 5.00 | 1.50 | 1.50 | 1.47 | 1.40 | 0.78 | 0.46 | 0.17 |

| >150 - ≤300 | d + 20 | 17.00 | 16.50 | 6.00 | 2.00 | 2.00 | 1.77 | 1.66 | 0.88 | 0.54 | 0.18 |

| >300 - ≤500 | d + 25 | 20.00 | 19.50 | 8.50 | 2.50 | 2.50 | 2.06 | 1.91 | 1.00 | 0.62 | 0.20 |

| >500 - ≤700 | d + 30 | 25.00 | 24.30 | 10.00 | 3.00 | 3.00 | 2.43 | 2.18 | 1.13 | 0.76 | 0.25 |

| Rod Seal, Single Acting, Hydraulics |

|---|

The dimensions s + c are dependent on the respective seal type.

Brightened symbols: seal only for limited use.

Please contact us

| Design | Application |

|---|

Surface Finish

| Roughness | Rtmax(µm) | Ra(µm) | Material Portion |

|---|---|---|---|

| Sliding Surface | ≤ 2.5 | 0.1 - 0.5 | Ratio contact area: 50 - 95% at a cutting depth of 0.5 x RZ starting from cref = 0% |

| Groove Base | ≤ 6.3 | ≤ 1.6 | |

| Groove Flanks | ≤ 15 | ≤ 3 |