Precision CNC Manufacturing of Hydraulic & Pneumatic Seals

Looking for CNC-machined hydraulic and pneumatic seals in the UK? At Rhondama Ltd, we specialise in precision CNC seal manufacturing using advanced lathes and tooling. From custom prototypes to production runs, we deliver high-quality seals in a wide range of elastomers and engineering plastics, all produced in-house at our Loughborough, Leicestershire facility.

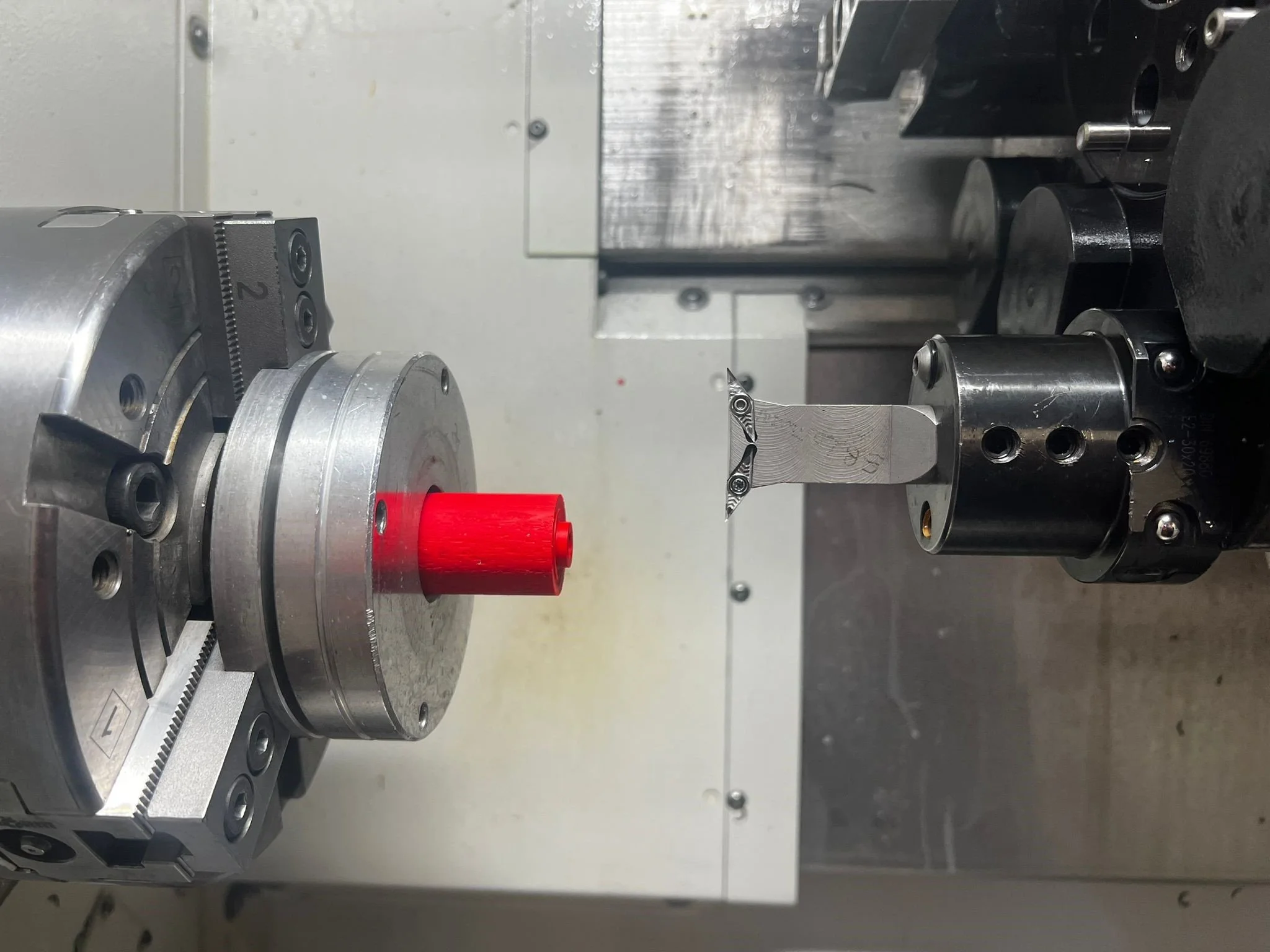

Our CNC Capabilities

Our machining facility is equipped with three in-house CNC lathes, enabling us to produce precision components from 5mm internal diameter (ID) up to 600mm outer diameter (OD).

We also offer:

Bar feed technology for efficient, continuous long-run production

Active tooling for complex milling and threading operations

Rapid production for custom, prototype, or small batch runs

This combination ensures short lead times, high accuracy, and consistent quality across all manufactured parts.

Materials We Machine

Explore our high-performance materials for hydraulic and pneumatic seals. Click each section to view detailed specifications, approvals, temperature range, hardness, and key properties.

| Material | Color | Approvals | Temp (°C) | Shore A | Shore D |

|---|---|---|---|---|---|

| NBR (Nitrile)Excellent oil and fuel resistance. Suitable for hydraulic & pneumatic seals. -30°C to +100°C. | -35 to +110 | 85 ±5 | |||

| NBR Solid (Nitrile)Excellent oil and fuel resistance. Suitable for hydraulic & pneumatic seals. -30°C to +100°C. | -30 to +110 | 90 ±5 | |||

| NBR White (Nitrile)Excellent oil and fuel resistance. Suitable for hydraulic & pneumatic seals. -30°C to +100°C. | FDA, EU 1935/2004 | -30 to +105 | 88 ±5 | ||

| NBR Soft (Nitrile)Excellent oil and fuel resistance. Suitable for hydraulic & pneumatic seals. -30°C to +100°C. | -35 to +110 | 73 ±5 | |||

| NBR Low tempreature (Nitrile)Excellent oil and fuel resistance. Suitable for hydraulic & pneumatic seals. -30°C to +100°C. | -50 to +105 | 82 ±5 | |||

| NBR metal detectable (Nitrile)Excellent oil and fuel resistance. Suitable for hydraulic & pneumatic seals. -30°C to +100°C. | FDA, EU 1935/2004 | -30 to +105 | 89 ±5 | ||

| X-NBR Solid (Nitrile)Excellent oil and fuel resistance. Suitable for hydraulic & pneumatic seals. -30°C to +100°C. | -30 to +110 | 89 ±5 | |||

| HNBR (Hydrogenated-Nitrile)Excellent oil and fuel resistance. Suitable for hydraulic & pneumatic seals. -30°C to +100°C. | FDA, EU 1935/2004 | -30 to +150 | 82 ±5 | ||

| HNBR Solid (Hydrogenated-Nitrile)Excellent oil and fuel resistance. Suitable for hydraulic & pneumatic seals. -30°C to +100°C. | -20 to +150 | 95 ±5 | |||

| HNBR Explosive Decompression (Hydrogenated-Nitrile)Excellent oil and fuel resistance. Suitable for hydraulic & pneumatic seals. -30°C to +100°C. | -30 to +150 | 88 ±5 | |||

| HNBR Soft (Hydrogenated-Nitrile)Excellent oil and fuel resistance. Suitable for hydraulic & pneumatic seals. -30°C to +100°C. | -35 to +150 | 75 ±5 | |||

| HNBR Metal Detecatable (Hydrogenated-Nitrile)Excellent oil and fuel resistance. Suitable for hydraulic & pneumatic seals. -30°C to +100°C. | FDA, EU 1935/2004 | -30 to +150 | 82 ±5 | ||

| FPM Brown(Viton®)Outstanding chemical and heat resistance. Ideal for high-temperature hydraulic applications. -20°C to +200°C. | FDA, EU1935/2004 | -25 to +220 | 85 ±5 | ||

| FPM White(Viton®)Outstanding chemical and heat resistance. Ideal for high-temperature hydraulic applications. -20°C to +200°C. | FDA, EU1935/2004, 3A-Sanitary class 1 | -25 to +210 | 84 ±5 | ||

| FPM Explosive Decopression(Viton®)Outstanding chemical and heat resistance. Ideal for high-temperature hydraulic applications. -20°C to +200°C. | -25 to +215 | 88 ±5 | |||

| FPM Soft(Viton®)Outstanding chemical and heat resistance. Ideal for high-temperature hydraulic applications. -20°C to +200°C. | -25 to +220 | 74 ±5 | |||

| FPM Metal Detectable(Viton®)Outstanding chemical and heat resistance. Ideal for high-temperature hydraulic applications. -20°C to +200°C. | FDA, EU 1935/2004 | -25 to +210 | 87 ±5 | ||

| MVQ White (Silicone)Flexible, excellent thermal stability, suitable for extreme temperatures. -50°C to +200°C. | FDA, EU1935/2004 | -60 to +210 | 84 ±5 | ||

| MVQ Blue (Silicone)Flexible, excellent thermal stability, suitable for extreme temperatures. -50°C to +200°C. | FDA, EU1935/2004 | -60 to +210 | 84 ±5 | ||

| MVQ Transparent (Silicone)Flexible, excellent thermal stability, suitable for extreme temperatures. -50°C to +200°C. | FDA, EU1935/2004 | -60 to +210 | 79 ±5 | ||

| MVQ Metal Detectable (Silicone)Flexible, excellent thermal stability, suitable for extreme temperatures. -50°C to +200°C. | FDA, EU1935/2004 | -60 to +210 | 88 ±5 | ||

| EPDMGood chemical, ozone, and weather resistance. Ideal for water applications. -50°C to +150°C. | -45 to +135 | 87 ±5 | |||

| EPDM SpringGood chemical, ozone, and weather resistance. Ideal for water applications. -50°C to +150°C. | W270 D1, Wras BS6920-1:2000 EU 1935/2004 | -50 to +135 | 87 ±5 | ||

| EPDM WhiteGood chemical, ozone, and weather resistance. Ideal for water applications. -50°C to +150°C. | FDA, EU 1935/2004 | -55 to +135 | 88 ±5 | ||

| EPDM SoftGood chemical, ozone, and weather resistance. Ideal for water applications. -50°C to +150°C. | -53 to +135 | 76 ±5 | |||

| EPDM White Soft Good chemical, ozone, and weather resistance. Ideal for water applications. -50°C to +150°C. | FDA, EU 1935/2004 | -50 to +135 | 77 ±5 | ||

| EPDM Metal DetectableGood chemical, ozone, and weather resistance. Ideal for water applications. -50°C to +150°C. | FDA, EU 1935/2004 | -50 to +135 | 84 ±5 | ||

| AFLAS®EDExcellent resistance to heat, chemicals, and steam. -10°C to +200°C. | - | -10 to +220 | 87 ±5 |

| Material | Color | Approvals | Temp (°C) | Shore A | Shore D |

|---|---|---|---|---|---|

| HPU PremiumHigh wear resistance, flexible, suitable for dynamic seals. Available in purple, blue, and red. -30°C to +120°C. | FDA | -30 to +115 | 94 ±3 | 49 ±3 | |

| HPU GreenHigh wear resistance, flexible, suitable for dynamic seals. -30°C to +115°C. | - | -30 to +115 | 94 ±3 | 49 ±3 | |

| HPU Low TemperatureHigh wear resistance, flexible, suitable for dynamic seals. -50°C to +115°C. | - | -50 to +115 | 94 ±5 | 47 ±3 | |

| X-HPU SolidHigh wear resistance, flexible, suitable for dynamic seals. -30°C to +110°C. | - | -30 to +110 | - | 58 ±3 | |

| HPU LubricatedHigh wear resistance, flexible, suitable for dynamic seals. -30°C to +110°C. | - | -30 to +110 | 94 ±3 | 49 ±3 | |

| X-HPU LubricatedHigh wear resistance, flexible, suitable for dynamic seals. -30°C to +110°C. | - | -30 to +110 | - | 58 ±3 | |

| HPU WhiteHigh wear resistance, flexible, suitable for dynamic seals. Compliant with FDA, EU1935/2004, EU10/2011. -30°C to +110°C. | FDA, EU1935/2004, EU10/2011 | -30 to +110 | 93 ±3 | 46 ±3 | |

| HPU SoftHigh wear resistance, flexible, suitable for dynamic seals. -30°C to +95°C. | - | -30 to +95 | 86 ±3 | - |

| Material | Color | Approvals | Temp (°C) | Shore A | Shore D |

|---|---|---|---|---|---|

| Acetal (POM, Delrin®)High strength, low friction, good chemical resistance. -40°C to +100°C. | FDA | -50 to +90 | 85 ±3 | ||

| Nylon (PA6/PA66)Good mechanical strength, wear and abrasion resistance. -40°C to +120°C. | -40 to +110 | 85 ±3 | |||

| UHMWPEUltra-high molecular weight polyethelene, excellent wear resistance, low friction. -200°C to +80°C. | -200 to +80 | ||||

| PTFE VirginLow friction, chemical resistant, can include Bronze, Carbon, Graphite, or MoS₂ fillers. -200°C to +260°C. | FDA | -200 to +260 | 58 ±3 | ||

| PTFE BronzeLow friction, chemical resistant, can include Bronze, Carbon, Graphite, or MoS₂ fillers. -200°C to +260°C. | -200 to +260 | 60 ±3 | |||

| PTFE CarbonLow friction, chemical resistant, can include Bronze, Carbon, Graphite, or MoS₂ fillers. -200°C to +260°C. | -200 to +260 | 62 ±3 | |||

| PTFE GlassLow friction, chemical resistant, can include Bronze, Carbon, Graphite, or MoS₂ fillers. -200°C to +260°C. | -200 to +260 | 58 ±3 | |||

| PTFE PeekLow friction, chemical resistant, can include Bronze, Carbon, Graphite, or MoS₂ fillers. -200°C to +260°C. | FDA | -65 to +240 |

Industry Approvals & Compliance

We offer materials that comply with leading international standards, including:

FDA (Food & Drug Administration)

EU1935/2004 (Food contact materials)

EU10/2011 (Plastic materials and articles in contact with food)

WRAS (Water Regulations Advisory Scheme)

This ensures our seals are suitable for food, beverage, water, and pharmaceutical applications.

Why Choose Rhondama For CNC Seal Manufacturing

In-house precision CNC machining for rapid production

Broad material selection covering rubber, polyurethane, and PTFE

Technical expertise in custom seal design and application support

UK-based production for fast turnaround and consistent quality

Prototyping to production — no minimum order quantities

Request a quote or contact us

Whether you need a custom hydraulic seal, a prototype pneumatic ring, or volume production, Rhondama Ltd can deliver the quality and precision you require.

Request a quote or speak with one of our engineers T: +44 1509 218149