Bearings

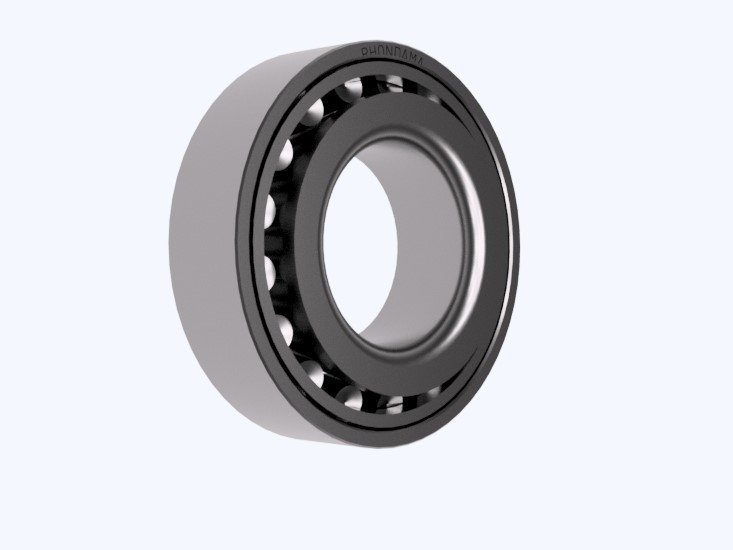

A Bearings main purpose is the prevention of metal-to-metal contact between two separately moving elements. This is to limit, or completely avoid, the heat that is generated and the friction between the two elements. Which will ultimately prevent the rapid wear and tear of any parts in the machinery.

The Bearing will also help with reducing energy consumption as any sliding motion is now replaced with a rolling motion, which will cause much less friction.

There is a large range of different kinds of Bearings that we can provide. Within each of these different styles of bearings are even more sub-styles of bearings. Such as:

-Ball Bearings

Deep Groove Ball Bearings

Angular Contact Ball Bearings

Self-Aligning Ball Bearings

Thrust Ball Bearings

-Roller Bearings

Cylindrical Roller Bearings

Spherical Roller Bearings

Tapered Roller Bearings

Needle Roller Bearings

Thrust Roller Bearings

-Plain Bearings

The choice of material for your bearing will depend on a few factors. These being the resistance to corrosion, porosity, durability, seizure resistance and simply cost saving.

The six most common Bearing materials are:

Carbon Steel Bearings

Chrome Steel Bearings

Stainless Steel Bearings

Ceramic Bearings

Polymer Plastic Bearings

Hybrid Bearings